The global air cargo security screening market was worth $4.8 billion last year, according to research by Exactitude Consultancy, and is projected to be worth $8.2 billion in 2034 with a Compound Annual Growth Rate (CAGR) of 5.6%.

The research says that the air cargo industry is transitioning towards automation with the development of AI- and machine learning-powered systems improving screening accuracy and operational efficiency.

It highlighted the challenges of regional disparity in regulatory frameworks and the costs of deploying advanced security technologies.

Growth will come from cargo demand with IATA forecasting global air cargo revenue of $169 billion by 2026, which will increase the need for screening solutions.

Authorities are mandating strict screening protocols, which means logistics firms must invest in high-tech solutions to avoid penalties.

Screening technologies are advancing with the introduction of CT scanners, automated threat detection systems and multi-view x-ray machines for faster and more accurate screening.

E-commerce is accelerating demand for faster and more secure shipping due to the volume of cross-border shipments.

The challenges highlighted in the report were the high capital investment requirements affecting small and medium-sized companies, regulations varying between countries, technological limitations as systems develop, the ongoing lack of skilled personnel and reluctance to replace legacy systems.

Canine senses

When Chris Daniels, Chief Strategy Officer of Global K9 Protection Group (GK9PG) entered aviation, his boss gave him the three goals of keeping all current business, win a United Nations contract and replace the Transportation Security Administration (TSA) in airports.

He was unconvinced about the last one but after completing the first two goals, Daniels started moving the pieces to make it happen.

After months of getting nowhere, Daniels met an old army contact who was working as a congressional liaison from the military to a senate member.

He suggested Daniels talk to the cargo industry who explained challenges and they worked together to fill the gap in the market.

Guided by the best mentors in the business, who made up for Daniels’ lack of cargo and logistics knowledge, they made good progress and when he left the job, he wanted to maintain the momentum and the private sector was allowed in, which led to the establishment of GK9PG.

Growing from four people around a kitchen table, GK9PG has become the largest company of its type in the USA and it is moving into other territories.

To keep air cargo safe and secure, the industry has to be right all of the time.

The operating space at airports does not change so this is a challenge if a new piece of kit is required, which is why GK9PG’s service is effective because the dog teams do not need permanent space in most cases.

The new year is likely to bring policy changes and it takes people time to implement them and they quickly work out the most effective method.

Daniels says, “Logistics in general figures out the solution as an industry because everyone is so interconnected that they work together to figure out how to enact policy changes or security guidelines in an effective manner. While you will run into some bumps in the road, the industry will get there.”

Canine teams are very effective security providers with the recurring joke that they have a smart and dumb end on the leash.

GK9PG links the canine’s senses with technology such as capturing video and connecting it with machine learning to automate processes like pulling in common data points, which are linked to other databases.

Processes report to client and common operating systems, which significantly reduces paperwork and save time.

Daniels adds, “Security is a layered approach. There is not one thing that will fixes every problem. You may have something that works the majority of the time, you’re going to run into specific situations that they will not be able to handle. With layering, you can use the right tool for the right job.”

GK9PG is looking to expand outside of the USA, starting with the acquisition of a small British company.

It has aligned with two major providers in the UK to provide services so GK9PG will enter several UK airports.

Daniels describes Europe as a unique challenge due to local and EU requirements so operations need to be structured for efficiency.

GK9PG has target cities in Europe and will expand where there is a client need.

Business is different in Europe with Daniels saying screening requirements both get to the same end point by taking different paths.

The US path was designed by business while the European path was a government creation.

Navigating the European business environment has been an interesting learning experience for the team.

Using the quote “things work out for those who work things out”, Daniels says, “You have got to keep working the problem and you will get to a solution. It takes resilience to push through barriers.”

Intelligent information

Using its Cargo Intelligence product, Pandora Intelligence uses air waybill information to give carriers, forwarders and handlers real-time assessments about compliance and safety, allowing them to take action before operations and revenue are impacted.

Product Manager Nicolo Comparini and Vice President of Product Gaetan van Diemen say this is made possible through its tailor-made AI models building extensive context based on the PLACI information from the AWB.

They say, “Cargo Intelligence can combine the analysis of the transported goods with an in-depth background check of shipper and consignee, identifying potential risks associated with the goods as well as the organisations even when the information provided in the airwaybill is of poor quality.”

The risk analysis is presented in a narrative so analysts can make decisions in a consistent manner.

The nature of AI means risk analysis are auditable and traceable so analysts can dig into data and make it possible to prove that all efforts were made to assess risks in case of disputes with authorities, they say.

Pandora Intelligence’s AI model is significantly more accurate than traditional detection models, such as keyword matching, which they say fail to consider the broader context of the shipment.

The model reduces false positives with Comparini and van Diemen giving the example of a glue gun, with the AI system knowing it is a tool, not a restricted military product.

The AI also picks up that a cordless glue gun contains a lithium battery so is classified as a dangerous good.

“By including background information about the shipper and consignee in the risk analysis, the AI models can derive the actual goods even when the commodity description is of poor quality or incomplete, allowing the system to even detect risks of mis-declared or undeclared goods,” they say.

The AI model can quickly adapt to regulatory changes, incorporating changes in rules and regulations so organisations can comply with changes more quickly.

To make the model accurate, specialised AI agents known as “domain experts” interpret and apply industry-specific regulations and frameworks for precise risk assessments.

Experts focus on areas such as military goods or dual-use goods, as examples.

Comparini and van Diemen explain, “This approach enables Pandora to accurately determine whether a shipment poses a regulatory risk and provides users with clear, regulation-specific justifications for its assessment.”

Since Cargo Intelligence was launched in 2019 through a collaboration between Pandora and a major European airline, it has processed AWBs from airlines of different sizes.

Cargo Intelligence has been integrated into the digital cargo ecosystem through partnerships with technology providers such as CHAMP Cargosystems, enhancing connectivity between key systems and improving operational efficiency.

“The decrease in undetected risks and sharp decline in false positives is being welcomed by a growing user-base operating globally from various hubs and regions. Senior staff particularly appreciates the ability to detect cargo risks before they can impact operations, revenue and brand reputation,” say Comparini and van Diemen.

The political and regulatory environment is becoming increasingly complex, and shifting international relations adds pressure on air cargo compliance, safety and security.

New technologies such as lithium batteries benefit portable devices but come with safety and security drawbacks.

The growth of e-commerce means larger cargo volumes and business, creating the challenge of timely risk assessments and increases the risk of undeclared goods and potential contraband.

The role of AI will increase in importance, with Comparini and van Diemen saying, “Looking at the functionalities we have been able to build with the help of AI in the last years, we are confident that most of our challenges can be solved with the right AI implementation, the challenge might rather become the timely availability of data and the quality of the data itself.”

Market evolution

Security providers have to constantly evolve to tackle threats and challenges, says Joachim Petry, Business Development Manager at Smiths Detection.

The security threats range from improvised explosive devices and home-made explosives to dangerous goods and contraband.

Improvised Incendiary Devices (IID) can be concealed within everyday objects, making advanced screening technologies critical.

Petry says, “Smiths Detection’s cutting-edge solutions, including X-ray computed tomography (XCT) and X-ray Diffraction (XDi), enhance the ability to identify such threats by providing high-resolution imaging and material discrimination. By leveraging these technologies, security operators can detect and mitigate potential risks, ensuring safer logistics and transportation networks.”

Security solutions are becoming more effective and efficient.

Petry says automation, intelligent networking and data analytics are playing an essential role in enhancing security, streamlining operations and ensuring regulatory compliance.

Smiths Detection has over 70 years of experience so understands air cargo industry requirements.

Petry says, “As a solutions architect, we work with customers worldwide to provide bespoke solutions that help them achieve their security and operational goals. Being a trusted partner that delivers innovative, best-in-class solutions is critical.”

Its solutions meet and exceed international air cargo screening requirements by combining outstanding detection capabilities with low false alarm rates and superior image quality.

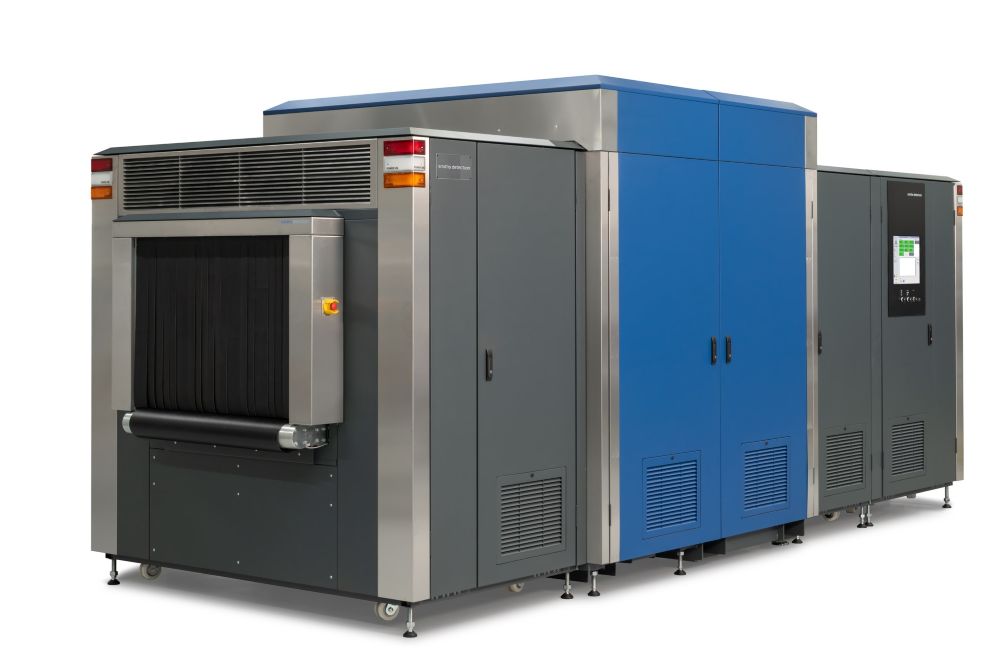

Smiths Detection has a range of scanners for different cargo types and customer needs such as its HI-SCAN 10080 XCT automatic explosive detection system which integrates with material handling systems for parcel screening, meeting the needs of express forwarders.

Large tunnel systems such as Smiths’ HI-SCAN 180180-2is can screen entire pallets.

CT scanners, which were originally designed for medical applications, are playing a crucial role in cargo inspections.

They generate volumetric 3D X-ray images for highly accurate assessments of shipment content, says Petry.

The systems are also evolving to be more energy efficient, making a contribution to sustainability targets.

He says, “Operator intervention is only required if the system flags suspicious items, enabling fewer operators to manage increasing shipment volumes. CT technology enhances security while improving efficiency and reducing costs.”

Automatic detection algorithms are enhancing CT scanners by continuously refining their ability to detect an expanding range of dangerous goods and contraband.

“Smiths Detection’s object recognition software, iCMORE, automates the identification of suspicious items within inspected cargo, baggage, or palletised goods, reducing operator workload and minimising errors,” explains Petry.

XDi technology is another major advance, detecting narcotics and explosives.

Smiths Detection launched its XRD-powered scanner, the SDX 10060 XDi in April last year.

The technology generates a unique diffraction fingerprint for molecular structures, which Petry says offers unparalleled material discrimination.

He says, “It accurately distinguishes between substances with similar densities, making it highly effective for detecting home-made explosives and narcotics.”

XRD can identify contraband whether it is in a solid, powder or liquid state.

Petry adds that detection libraries can be updated when needed.

Operating at a constant speed with non-intrusive, highly specific and rapid detection, XRD is effective for high-volume, high speed environments such as parcel processing, says Petry.

Petry adds that open architecture has the power to transform cargo security through seamless interoperability between hardware, software and algorithms between multiple suppliers.

This allows security operators to integrate and upgrade technology from trusted suppliers so they can adapt as security challenges evolve.

Petry says, “The future of air cargo security will rely on data-driven risk assessments and integrated sensor networks. This requires open equipment interfaces, common data formats, and an oversight mechanism to ensure compliance with technical standards, certification, and liability considerations.”

This article was originally published in the March/April 2025 issue of Air Logistics International, click here to read the digital edition and click here to subscribe.