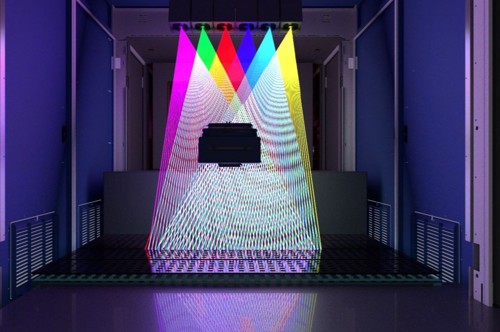

Picture credit: CEIA

The air cargo security threats are determined by civil aviation authorities based on their risk assessment, says Nicolas Ouakli, Cargo and Mail Screening Equipment – Global Solutions Manager at CEIA.

He explains that the threats have affected how explosive and incendiary devices have developed since the International Civil Aviation Organization (ICAO) started defining common air cargo security guidelines.

Ouakli says, “The main threat for air cargo security is the use of Improvised Explosive Devices that tend to evolve constantly in terms of shape and components although they all tend to share the same characteristics of explosive material, a trigger circuit, a detonator and a battery.”

CEIA’s air cargo security devices focus on detecting metallic components used to make IEDs by analysing the electromagnetic profile of the commodities screened.

“The advantage of electromagnetic inspection is that the detection performances do not change with regard to the variations in shape/nature of the components used to make IEDs,” says Ouakli.

All IEDs share the same characteristics and include metallic components, so electromagnetic inspection provides significant advantages, adds Ouakli.

EMIS devices are under the category Metal Detection Equipment or Cargo Metal Detector to screen non-metallic commodities.

Regulations state that they must detect the presence of IEDs by focusing on the metallic and conductive components such as detonators and batteries.

Important though technology is, in Ouakli’s opinion, new screening methods, technology and using Artificial Intelligence will not resolve everything.

Many possibilities and methods are available but they are not implemented equally and even when all methods are approved, they are often not exploited to their full potential, says Ouakli.

Ouakli believes that all ICAO member nations should agree on a common regime then civil aviation authorities should agree on the same guidelines and stringent standard operating procedures to provide the same level of security everywhere.

He says, “The lack of harmonisation remains one of the main challenges as it creates discrepancies that may lead to weak spots in the supply chain’s security. The only way to overcome these issues is for the authorities to work together with the supply chain stakeholders and manufacturers.”

Providing the right solutions

Explosives are the primary focus for air cargo security but there are increasing safety threats from dangerous goods including lithium batteries, and from prohibited items and contraband such as narcotics, illegal currency, fireworks and bio-threats, says Joachim Petry, Business Development and Product Manager Air Cargo at Smiths Detection.

Petry says, “With accelerated growth in international trade and e-commerce, very short delivery times and more interconnected global supply chains, the need for efficiency across the air cargo ecosystem, both in mandatory security screening and in screening for contrabands or dangerous goods, has only increased.”

Smugglers are always coming up with new methods to conceal security threats so the technology needs to adapt.

Security solutions are more effective and efficient with automation, intelligent networking and data analytics capabilities playing an essential role in boosting security, creating operational efficiencies and assisting with regulatory compliance.

Computed topography (CT) scanners are playing a pivotal role by generating volumetric 3D X-ray images to view shipments from all angles.

The data acquired offers a highly accurate assessment of shipments and operators only need to intervene when the system identifies something suspicious, says Petry.

He says, “This streamlined process allows fewer operators to manage increasing shipment volumes. CT technology not only upholds the highest security standards but also enhances operational efficiencies and productivity, leading to cost reductions.”

Automatic detection algorithms are enhancing CT scanners by learning to identify different dangerous goods and contraband. Petry says the algorithms can be refined through machine learning techniques as threats evolve.

“Smiths Detection’s object recognition software, iCMORE, reduces the burden on operators – and potential errors – by automating the detection process for suspicious items within inspected cargo, baggage or palleted goods and makes it easy to identify more of what could be passing through an operation,” says Petry.

X-ray diffraction (XRD) technology is a step change for detection, says Petry, saying it provides highly accurate identification of molecular structures and even higher levels of accuracy analysing materials and detecting substances.

It can be used to automatically clear alarms generated by CT scanners and identify hard to detect substances.

Petry says, “By automatically clearing false alarms or benign objects, the need for Level 2 on-screen resolution, hand searches, trace detection or other manual inspections is substantially reduced.”

Enhanced network capabilities combined with data analytics and connectivity offer benefits, says Petry, explaining that wide-area networks (WAN) are a key element for centralised and remote image evaluation.

Remote screening has been used for passenger baggage but is new for cargo operations and is particularly useful at regional handling facilities with fluctuating volumes.

He says, “Connecting all remote locations to a central location with more consistent cargo volumes allows for more efficient deployment of operators, eliminating the need to maintain staff onsite at smaller sites around the clock.”

Open architecture offers integration of algorithms and hardware between different suppliers into a unified solution, which is a key area of development as the future of air cargo security depends on data-driven risk assessments.

It will deliver benefits including greater flexibility and accelerated innovation, with Petry saying third-party algorithms, data sharing and centralised image processing are essential to achieving this.

Adopting different screening methods is another major step to enhance air cargo security with aggregated data from various sources providing a more refined risk analysis.

Different security measures could be triggered automatically in response to changing threats, says Petry.

“The most obvious benefit is the intelligent use of additional resources to increase security. The flexibility of risk-based screening should also deliver a screening process which can adapt to changing circumstances whilst complying with privacy and data protection concerns. The technical means to introduce risk-based screening are available now,” says Petry.

Improving existing products is vital to improve security so Smiths Detection is constantly improving its iCMORE smart detection algorithms and enhancing digital solutions.

CT and XRD technology are likely to combine into one unit, Petry believes, checking items with both technologies simultaneously.

With rising automation and digitalisation, staff need to be trained so this is an area of development for Smiths Detection, with Petry commenting, “We strongly believe that the best security and operational outcomes are achieved when people and machines work in harmony.”

Smiths Detection is developing training solutions with customers and it is important to understand that one size does not fit all, it is important to understand how operators interact with equipment.

“A competent operator is one that has the appropriate knowledge, skills, behaviours and experience to conduct their role effectively, it is therefore our responsibility to ensure that our training meets the customers needs if we are to make the world a safer place,” concludes Petry.

This article was published in the February 2024 issue of Air Logistics International, click here to read the digital edition and click here to subscribe.